Normal ship operations generate hydrocarbon waste which at one time would have been discharged at sea. But in 1973, the need to protect our fragile marine ecosystem prompted the IMO (International Maritime Organization) to adopt the MARPOL Convention, setting the guidelines for the collection and treatment of this waste.

There are various types of hydrocarbon residues. Some come from land-based activities, including industrial oil residues and used lube oil, while others are generated at sea and are commonly known as slops. The generic term “slops” covers various types of hydrocarbon residues generated by normal shipping activity. These residues are composed of water, hydrocarbons, and different pollutants, in varying proportions.

Considered industrial residues, maritime waste is collected in ports, an expense borne by shipowners. Since their composition can vary and the nature of these pollutants (sediments, heavy metals) makes them difficult to recycle, they are usually incinerated.

Slops, generated by the commercial activity of oil tankers, are a mixture of water from cleaning tanks and cargo residues.

Slops, generated by the commercial activity of oil tankers, are a mixture of water from cleaning tanks and cargo residues.

Sludges, meanwhile, are generated in machine rooms. They mostly comprise hydrocarbon residues generated by purifying fuels used for engines and boilers,as well as used lube oil and hydraulic oil.

Land residues can come from the accidental mixing of hydrocarbons, from the unblocking or purging of pipelines, from products outside commercial and technical specifications, or from the bottom of containers, etc.

Land residues can come from the accidental mixing of hydrocarbons, from the unblocking or purging of pipelines, from products outside commercial and technical specifications, or from the bottom of containers, etc.

Used lube oil can also be found in land-generated hydrocarbon residues. Since these residues contain a high concentration of pollutants (including metals), used lube oil from engines is among the most toxic waste there is. One liter of waste oil can pollute up to 1,000 m2 of water, preventing the oxygenation of sub-marine flora and fauna for several years.

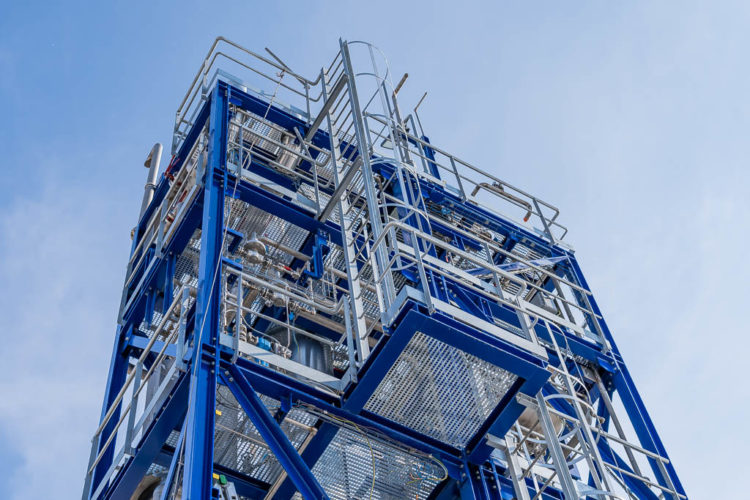

With its innovative waste-recovery technology, Ecoslops can improve the efficient use of this resource. The company offers its industrial partners (shipowners, port terminals, producers, O&G companies, etc.), waste collectors, and other institutional actors an economical, more environmentally friendly, and transparent solution that complies with international regulations on the collection and treatment of these residues.

Are you a buyer of petroleum products?

We offer a range of special light fuels, naphtha, gasoil, industrial heavy fuel, and soft bitumen recycled at our units in Europe.

The products from our Sines unit are ISCC PLUS certified. This certification provides credible and transparent proof that the hydrocarbons recycled by Ecoslops Portugal contribute fully to the circularisation of the economy, an additional advantage for our environmentally conscious customers.

The products from our Sines unit are ISCC PLUS certified. This certification provides credible and transparent proof that the hydrocarbons recycled by Ecoslops Portugal contribute fully to the circularisation of the economy, an additional advantage for our environmentally conscious customers.

Ecoslops draws on its fifteen years of recycling experience and ample capacity to receive and store waste products. We can also assess the recycling needs of all types of hydrocarbon waste (high and low flash points).

A TRACEABLE SOLUTION

A TRACEABLE SOLUTION

Each stage of the treatment process is traceable and transparent. All stakeholders can rest assured that the treatment of these residues complies with international and local regulations.

A SUSTAINABLE AND ECONOMICAL SOLUTION

Thanks to sustainable purchasing conditions, Ecoslops offers long-term opportunities for oil residues, making their collection and treatment a viable business.

A MORE ENVIRONMENTALLY-FRIENDLY SOLUTION

The P2R process recycles more than 98% of dehydrated oil residues. This is a circular economy solution that helps preserve fossil resources and improve the sector’s material balance by avoiding new extractions. Recycling hydrocarbon waste also helps to reduce illegal dumping (maritime and land).

A TRACEABLE SOLUTION

A TRACEABLE SOLUTION